In the lighting industry, “dual color temperature adjustment” has long been commonplace. Whether in offices, hotels, or living rooms, the ability to freely switch between warm white and cool white seems to have become a standard feature of smart lighting.

However, many designers and users find that when the color temperature is set to an intermediate value, something seems “off”—some lights show a noticeable decrease in color rendering, while others take on a pinkish or greenish tint.

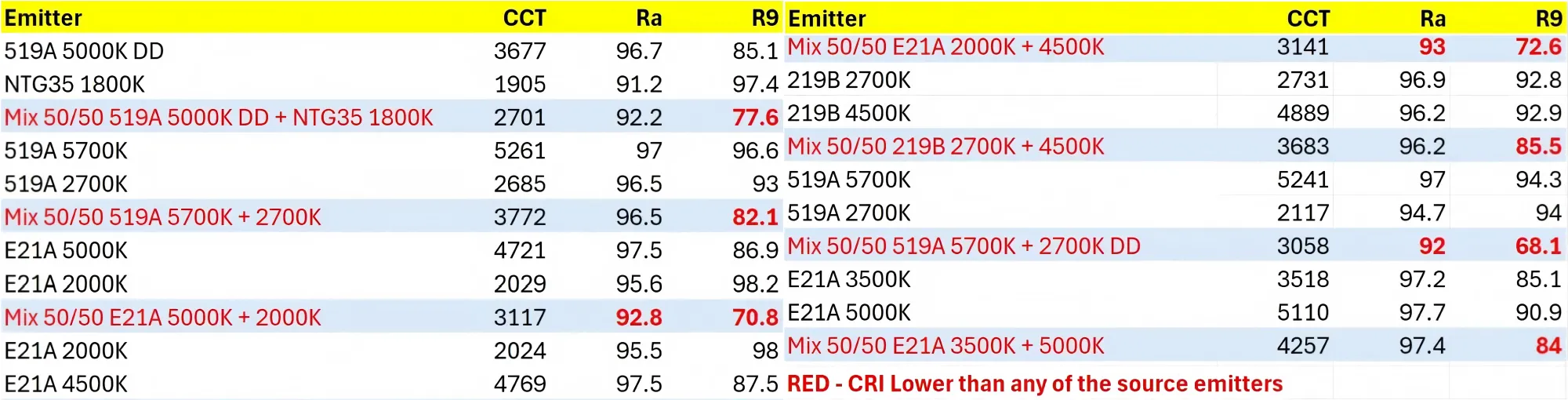

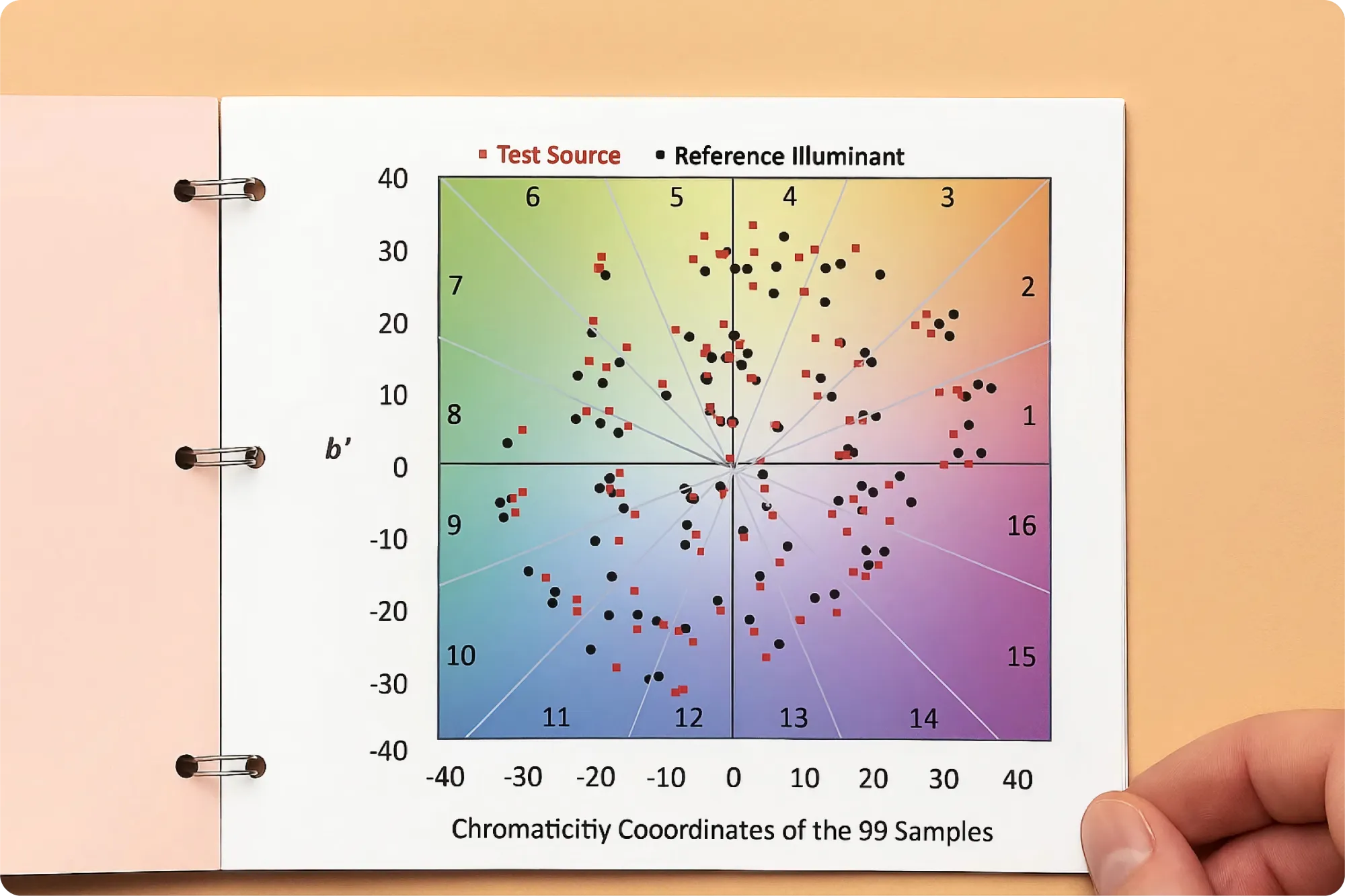

Figure: After mixed dimming of dual-color temperature LEDs with high CRI, both Ra and R9 decrease significantly.

This is not an illusion, but rather the inevitable result of the dual-color temperature LED mixed lighting principle. This article will use the most rigorous technical logic to help you understand the reasons behind this phenomenon and provide professional recommendations for improvement.

1. The Scientific Language of Light Quality

Before discussing the consistency of dual-color temperature mixed lighting, we must first establish a common “optical language,” including:

Spectral Power Distribution (SPD) – The “fingerprint” of a light source, determining all characteristics such as color temperature and color rendering.

- Incandescent light has a continuous and smooth spectrum, while the SPD of white LEDs is composed of blue light chips and phosphors, typically featuring a sharp blue peak and segmented yellow/red bands.

- In a dual-color temperature system, the SPD differences between warm white (e.g., 2700K) and cool white (e.g., 6500K) are significant, and mixing them inevitably results in a new spectral profile.

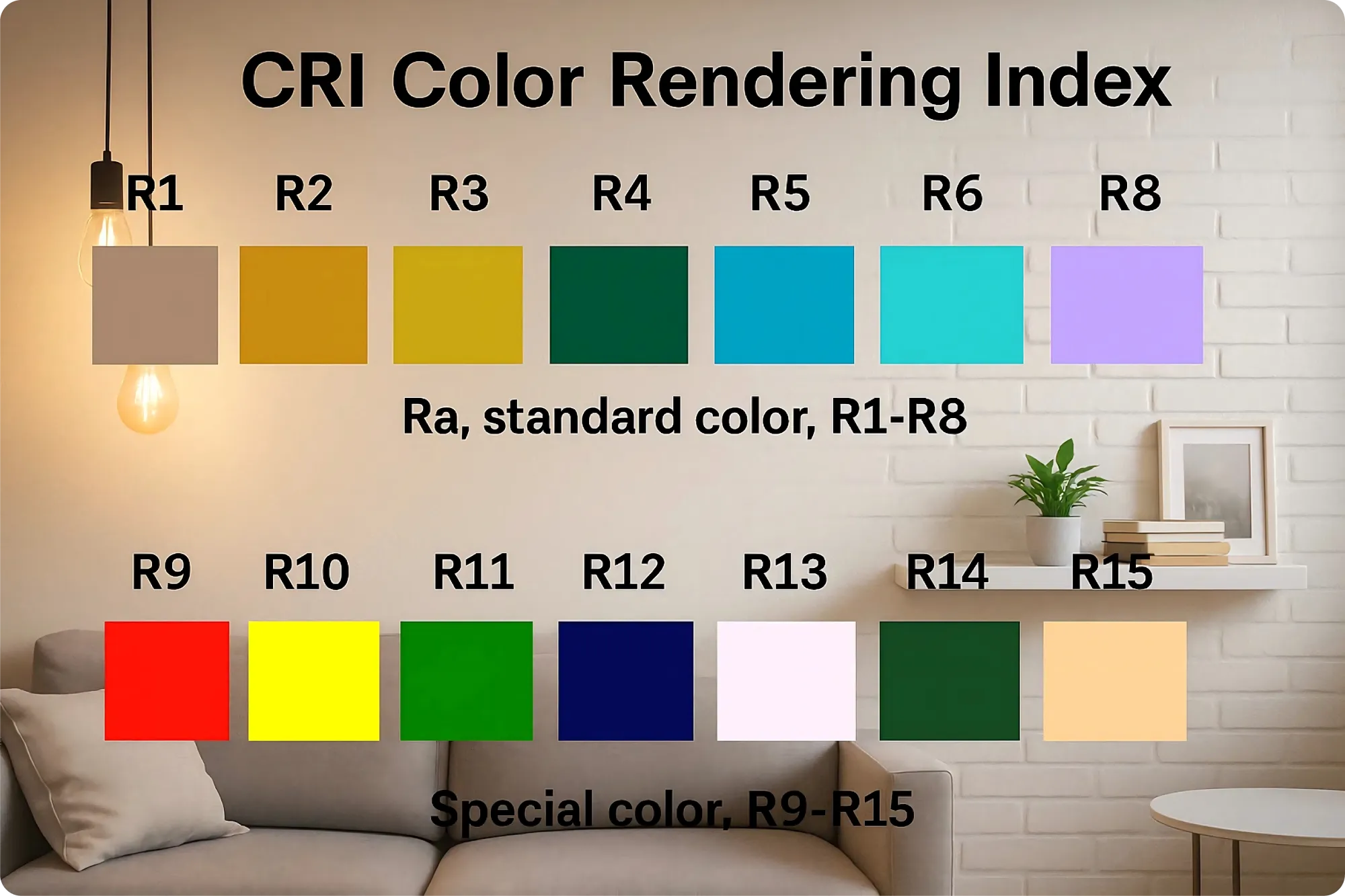

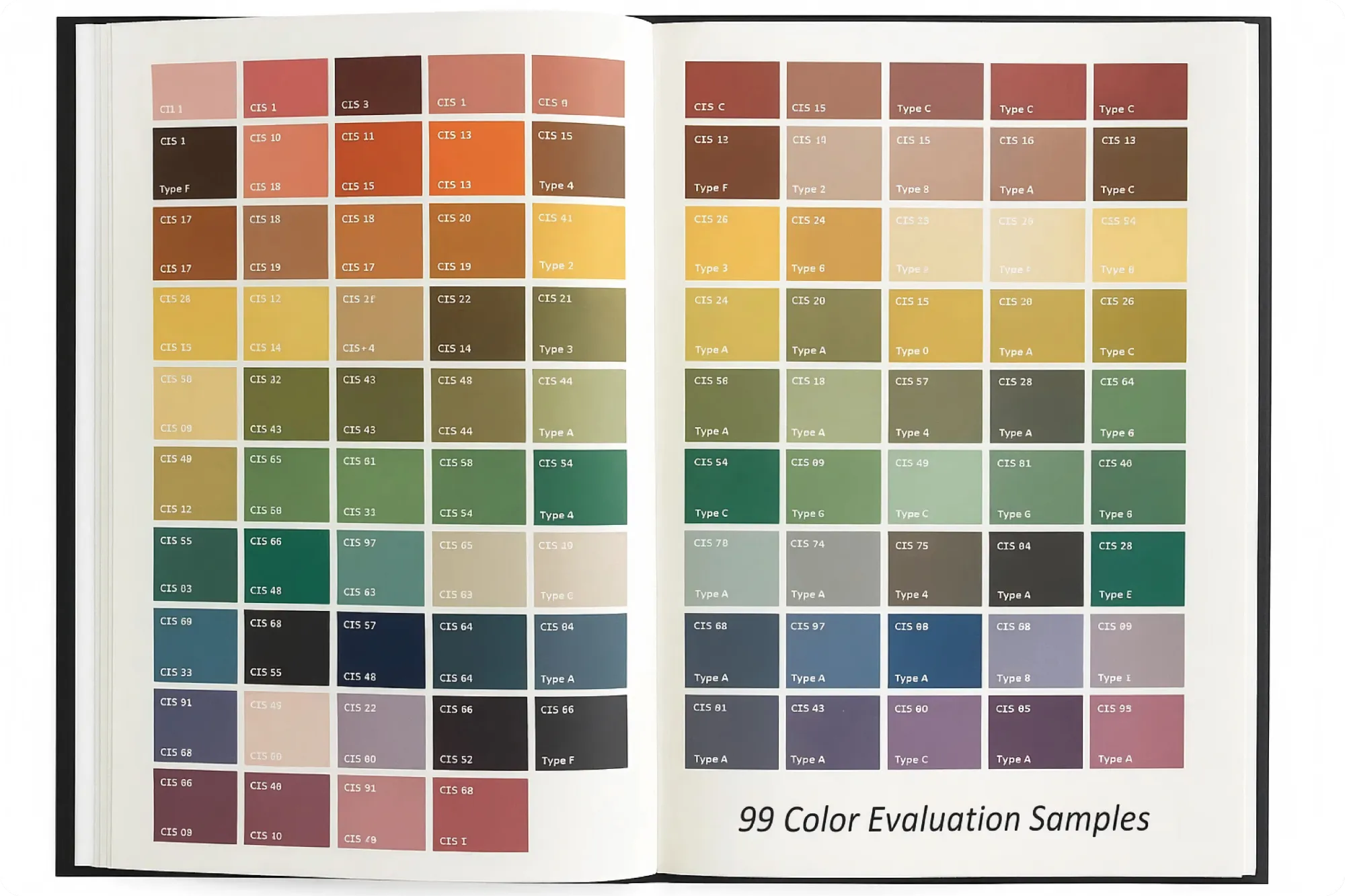

Color Rendering Index (CRI, TM-30)

- CRI Ra: An internationally recognized standard used for decades, but it only evaluates eight low-saturation test color samples, making it susceptible to “optimization” that results in high numerical values but poor actual color reproduction.

- R9: Saturated red color rendering index, critical for skin tones, wood, and meat. Light sources with high Ra but low R9 often cause colors to appear grayish.

- TM-30: An upgraded version launched by IES North America, adding dual indicators of Rf (fidelity) and Rg (saturation), and using color vector diagrams to visually display color deviation direction and magnitude, providing a more comprehensive assessment than CRI.

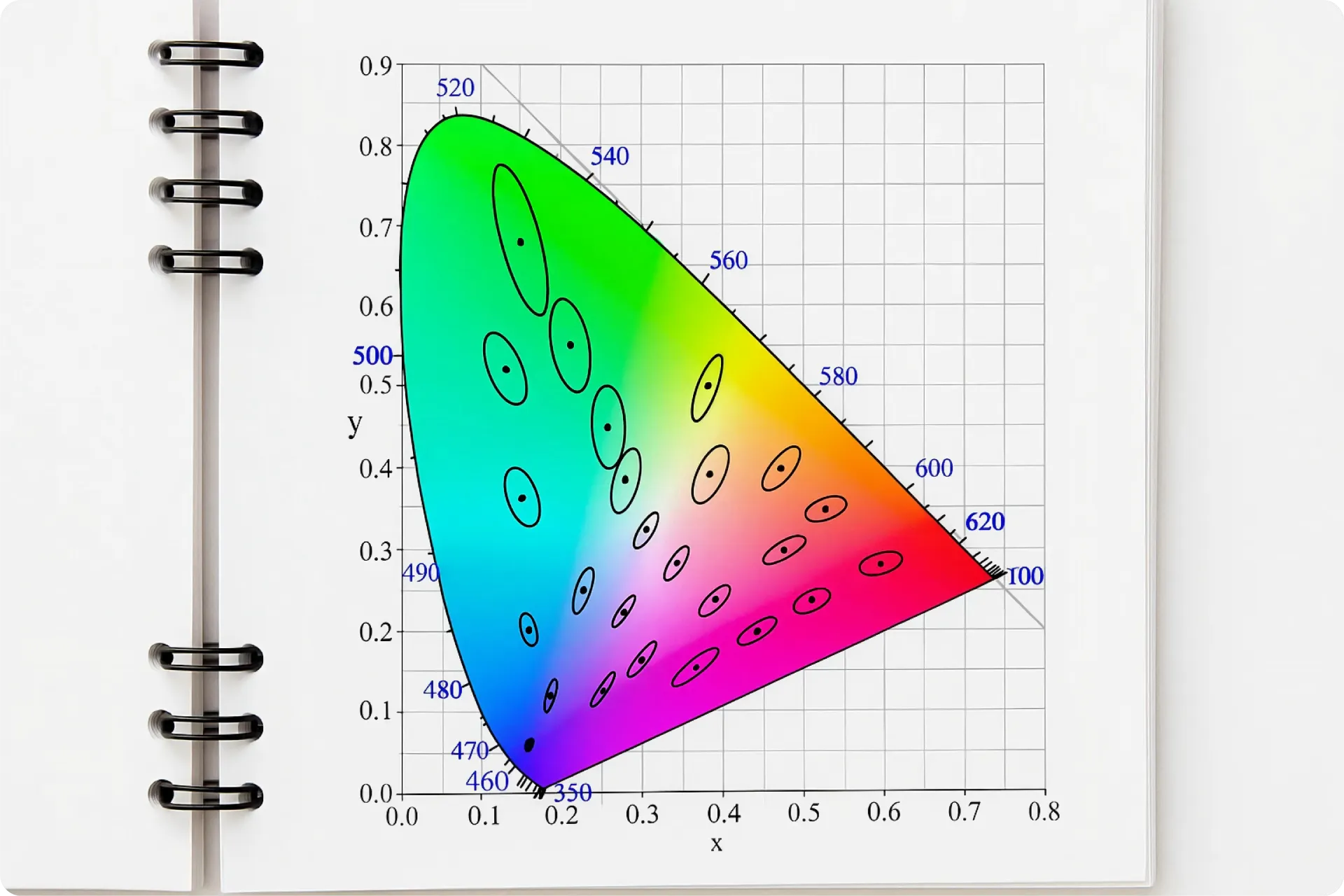

Color difference (SDCM) and MacAdam ellipse

- LEDs from the same batch may also have slight color differences, and SDCM is an indicator that quantifies this difference.

- High-quality lighting usually requires 2-3 steps of SDCM, but this is only a chip-level indicator, and system consistency also depends on optical design and drive accuracy.

2. Geometric limitations of dual-color temperature mixed lighting.

The dual color temperature system consists of a warm white channel and a cool white channel. When adjusting the color temperature, the two SPDs are essentially linearly superimposed at different ratios.

The issues are:

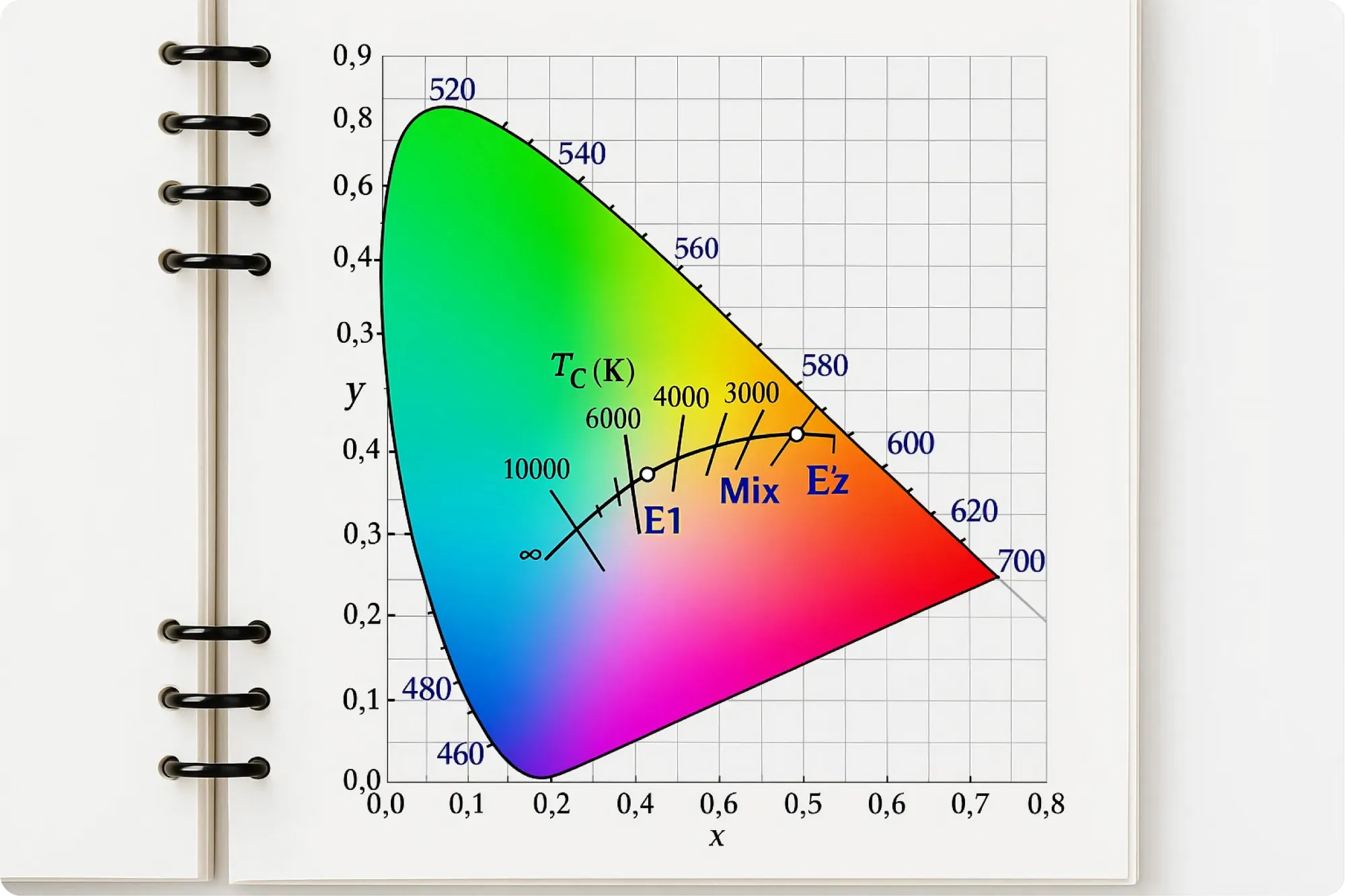

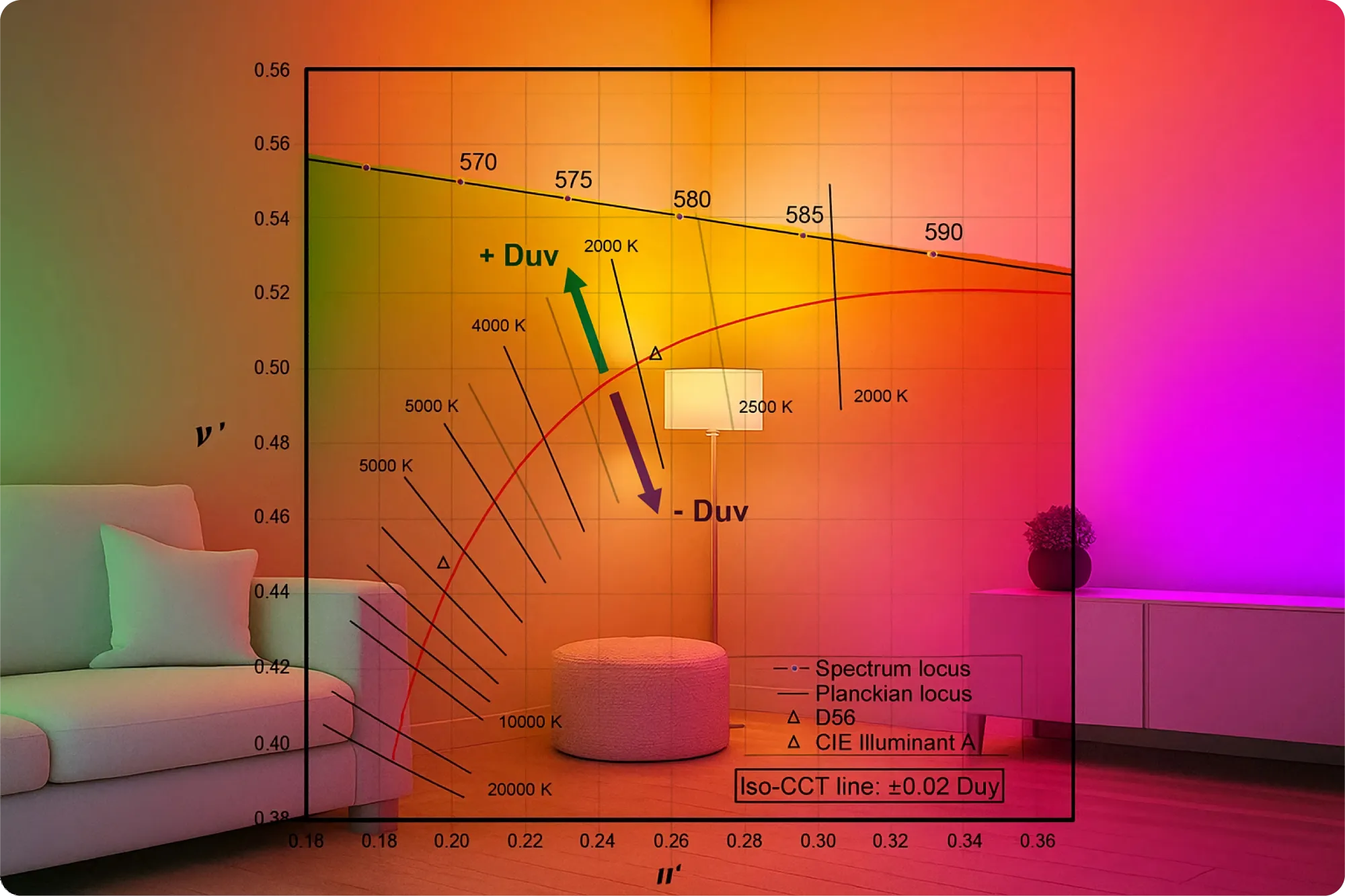

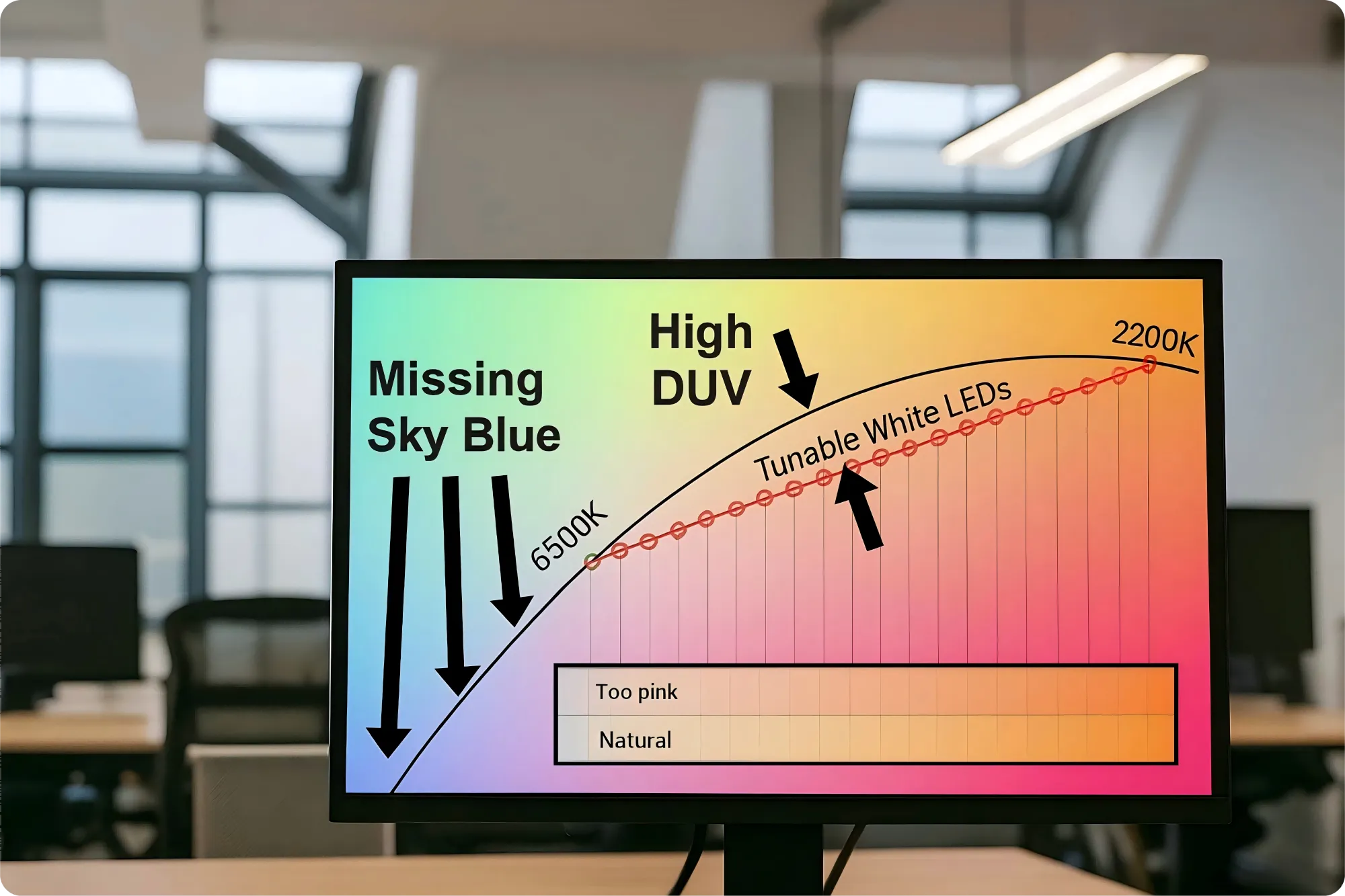

- On the CIE chromaticity diagram, the color trajectory produced by mixing is a straight line, while the ideal white light (blackbody trajectory BBL) is a curved line.

- When adjusted to an intermediate color temperature, this straight line inevitably “cuts across” the BBL from below, resulting in a systematic negative Duv offset, which manifests as a noticeable pink or magenta tint.

This means that even if the color temperature perfectly aligns with the BBL at both endpoints, color deviation in the intermediate range is physically unavoidable.

Figure: Illustration of DUV deviation from the convergence curve

3. Why does color rendering collapse at intermediate color temperatures?

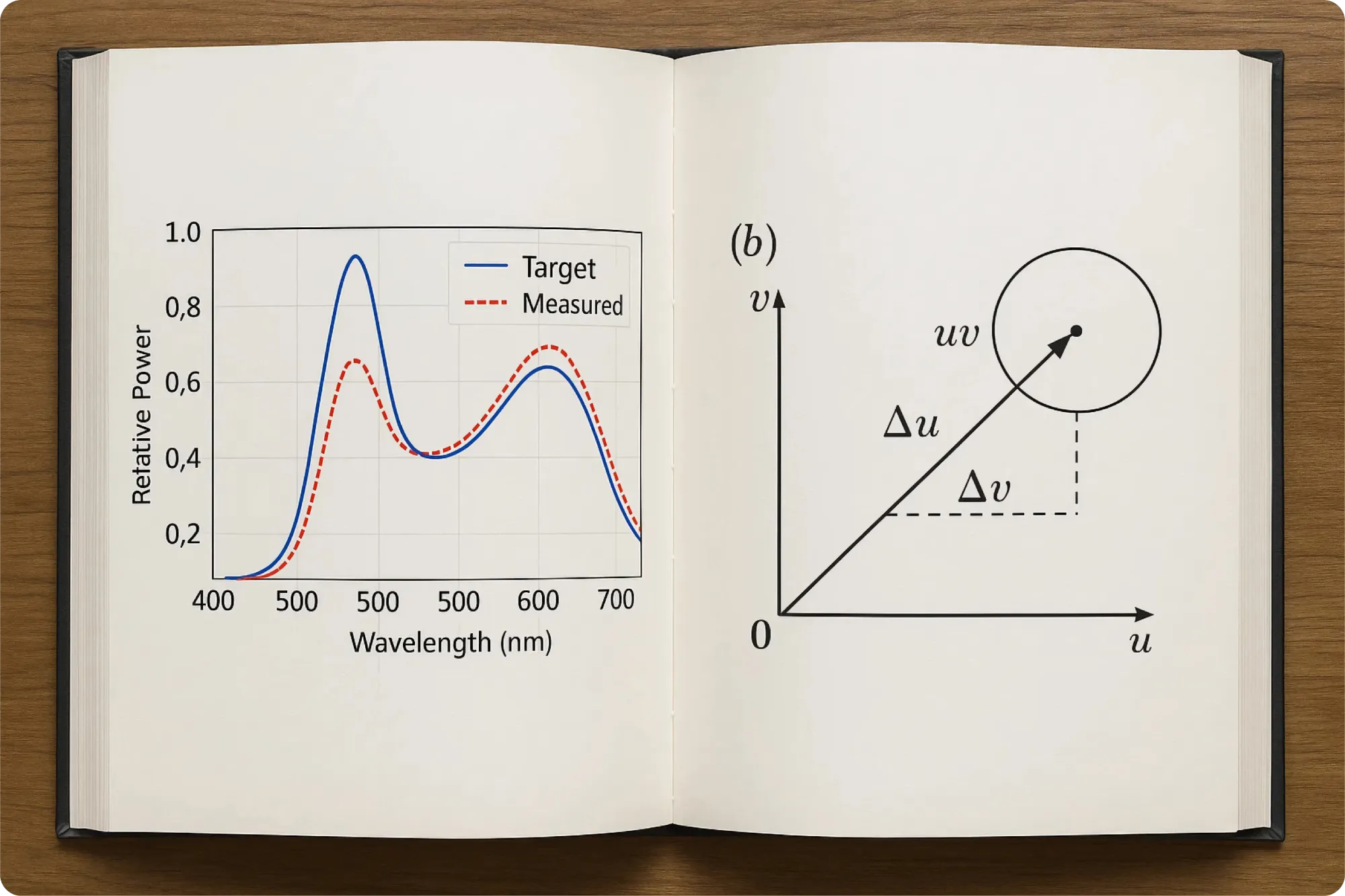

In actual testing, the CRI and Rf of dual-color temperature LEDs often show a noticeable “dip” in the middle range (3500K~4500K), especially with a significant drop in R9.

There are three reasons:

- Spectral gaps:Warm white and cool white LEDs each have their own strengths and weaknesses, and mixing them in the mid-range can result in energy “valleys” in critical regions such as 480–560 nm.

- Metamerism failure:While the SPD of mixed light can achieve the same color temperature, it is completely different from the true single-color-temperature spectrum, leading to color reproduction distortion.

- TM-30 reveals saturation changes:The mid-range color temperature Rg often increases (over-saturation), making colors more “vibrant,” but reducing color fidelity. This may be an advantage in retail settings, but it is a critical flaw in high-fidelity environments such as museums and medical facilities.

4. Color tolerance consistency is not just about chip grading

Many people believe that selecting LED chips with a 2-3 step SDCM can ensure system color consistency, but in reality, there are three major risks:

- Insufficient optical design→ Uneven mixing of light, resulting in color fringing and color spots.

- Insufficient driver precision→ CCT drift during dimming, especially noticeable at low brightness levels.

- Lack of spatial and temporal stability→ Increased color differences at different angles and over extended usage periods.

5. How to break through the limits of dual color temperature?

To fundamentally solve the problem of color rendering and color tolerance consistency, the industry has begun to adopt a multi-channel spectral adjustment strategy:

- Three-channel: Adding neutral white between warm white and cool white significantly improves Duv offset.

- Four/five-channel (RGBW, RGBAW):Introducing independent primary colors such as red, green, blue, and amber, the algorithm can optimize SPD under metamerism conditions, achieving:

~ Full-range BBL matching (Duv ≈ 0);

~ Full-color temperature high color rendering (Ra > 90, R9 > 90);

~ Controllable spectral continuity, supporting human-centric lighting, specific color enhancement, and other applications.

Although multi-channel systems have higher costs and control complexity, they are the only solution capable of simultaneously meeting the dual high requirements of color rendering and consistency in high-end lighting and color-critical applications.

6. For designers and buyers: Look beyond just CRI and SDCM.

- Don’t just look at CRI or SDCM,

Request TM-30 reports for endpoint and midpoint color temperatures, Duv data, and dimming stability curves.

- Evaluate the system, not the components,

Examine optical mixing solutions and driver control precision, rather than just focusing on LED chip specifications.

- Application scenarios determine technology selection,

Optimized dual-channel systems are suitable for general office use; museums, healthcare, and art applications must select multi-channel spectrally adjustable solutions.

Author

Andy Gao

With 15 years in the LED lighting industry, I’ve witnessed its evolution from general fixture production to today’s highly specialized segments. As Co-Founder of Veldstar, my journey mirrors this shift – driving our exclusive focus on pergola and garden lighting solutions. Through dedicated innovation, we develop controllers and systems rivaling leaders like Somfy and Teleco. Here, I share insights and showcase products engineered to elevate outdoor spaces with style, functionality, and advanced control. Learn more via linkendin profile:https://www.linkedin.com/in/pergolalights/

Share This Article:

Send Us your Request