Why 10.6mm or 11mm LED Profile Are Costing You Time, Money, and Flexibility.

As specialists in LED lighting systems for high-end bioclimatic pergolas and verandas, we’ve observed a persistent industry hurdle: the use of non-standard LED profile widths like 10.6mm or 11mm. While seemingly minor, these specifications create unnecessary complexity for architects, installers, and homeowners. Here’s why this matters—and how our standardized solutions streamline your projects.

The Problem: When “Close Enough” Isn’t Good Enough

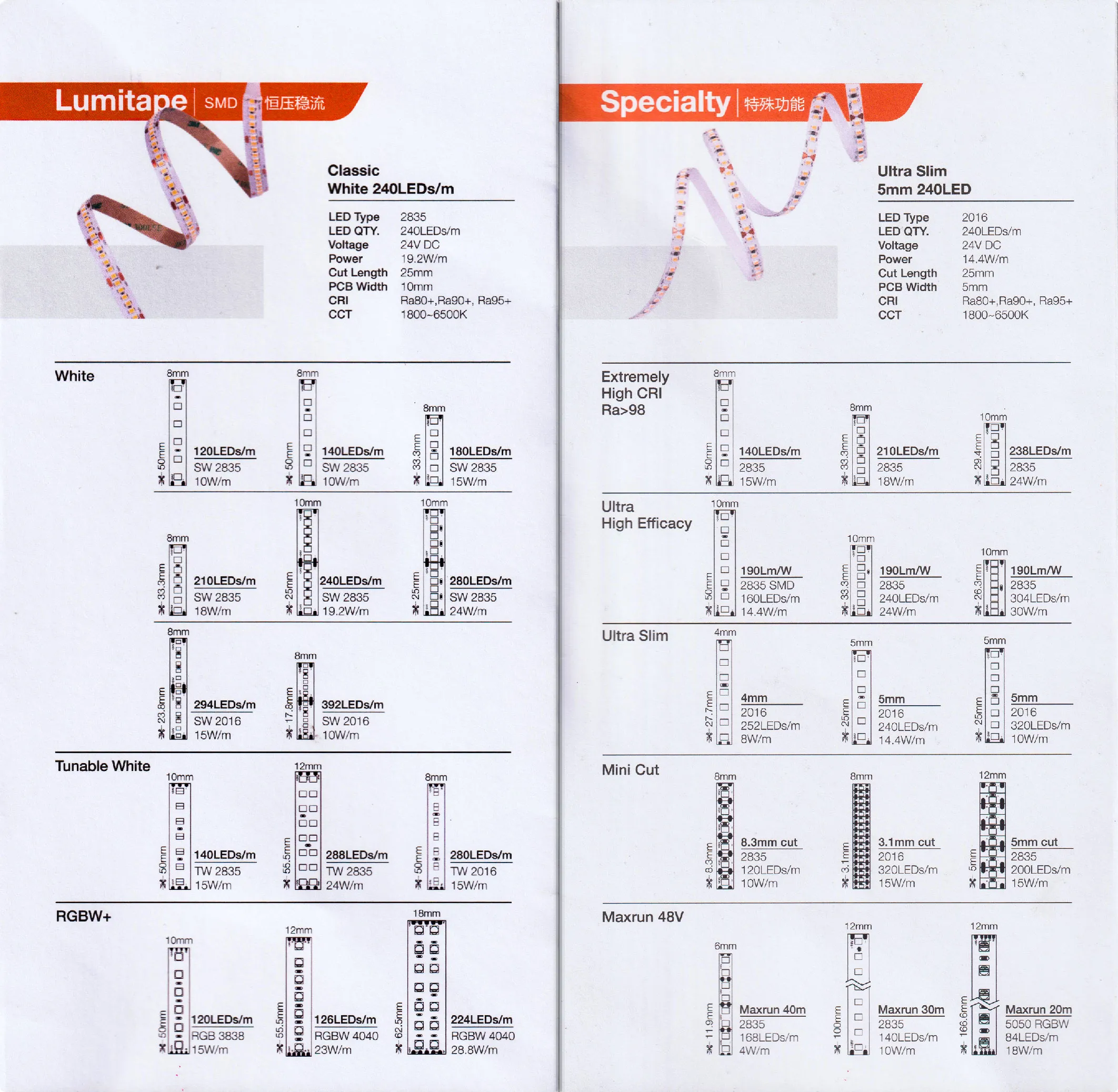

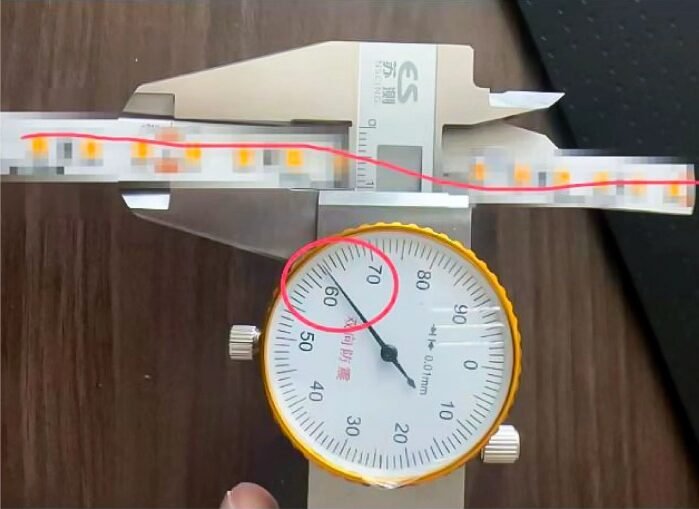

Many premium pergola manufacturers design extrusion channels with tight tolerances, leading to niche LED strip requirements like 10.6mm or 11mm. This creates a number of problems because of the width of the regular strips: 8 mm, 10 mm, 12 mm.

Supply Chain Delays: Sourcing specialty profiles means longer lead times and minimum order quantities. If aluminum profiles manufacturers and LED flexible strips manufacturers can’t harmonize their standards:

Incompatibility Risks: Non-standard widths limit strip options, forcing users to customize the production of a particular type of strip.

Fragile Ecosystems: If your LED profile supplier or LED strip supplier goes out of business, the entire project comes to a standstill.

After supporting 500+ pergola/veranda projects globally, we standardized our LED profiles and controllers around universal widths (8mm, 10mm, 12mm). Here’s how this benefits you:

Why Universal Standards Win: The 8mm/10mm/12mm Advantage

1.Plug-and-Play Flexibility

Our connector and cable integrate seamlessly with industry-standard profiles. No more custom wiring or compatibility guesswork.

2.Future-Proof Installations

Standardized profiles or strips ensure replacements/upgrades are readily available—years after installation.

3.Cost Efficiency

Eliminate markup for “special sizes.” Save 15-30% on profiles alone with bulk-available universal options.

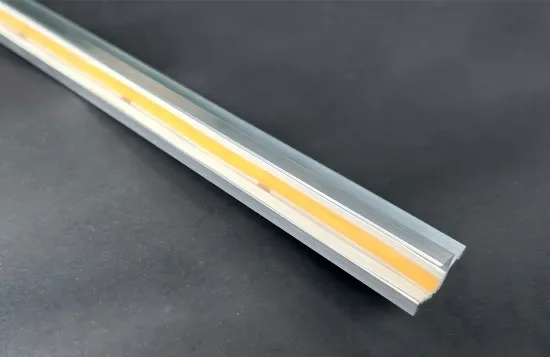

Although, There have a Case in Point: The 10.6 mm Dilemma Solved

A recent client struggled with 10.6mm profiles delaying a luxury veranda project. By switching to our 10.6mm strips + adaptive end cap, they achieved:

✅ 48-hour component delivery (vs. 4-6-week wait);

✅ 22% cost reduction on lighting hardware;

✅ Flawless fit with existing extrusions.

✅ Freecut with minimum 1mm per cut!.

Your Lighting, Simplified

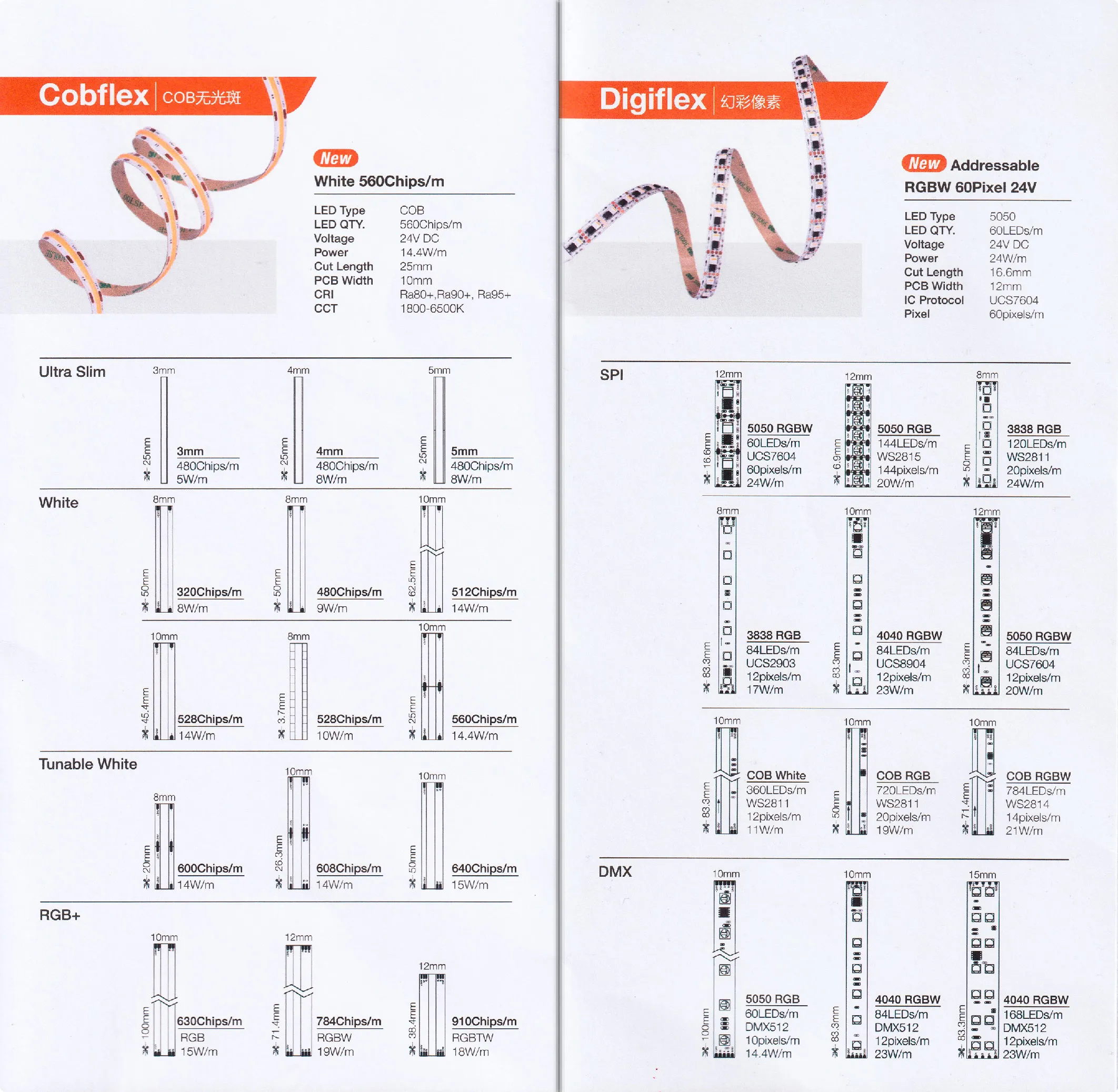

We design for real-world pergola strips. Our LED flexible strips y smart end caps deliver: Perfect Fit Guarantee: Tolerance-engineered for snap-in installation. Global Stock Availability: No project delays.

→ Explore Our Special pergola LED flexible strips:

Technical Support: Send us your extrusion specs—we’ll validate compatibility within 24 hours.

Author

Andy Gao

With 15 years in the LED lighting industry, I’ve witnessed its evolution from general fixture production to today’s highly specialized segments. As Co-Founder of Veldstar, my journey mirrors this shift – driving our exclusive focus on pergola and garden lighting solutions. Through dedicated innovation, we develop controllers and systems rivaling leaders like Somfy and Teleco. Here, I share insights and showcase products engineered to elevate outdoor spaces with style, functionality, and advanced control. Learn more via linkendin profile:https://www.linkedin.com/in/pergolalights/

Share This Article:

Send Us your Request