The quality of a light fixture hinges not merely on the LED chips, but on its ‘heart’ – the power supply. Are you selecting an isolated or non-isolated power supply? Do not underestimate this decision, issues can range from flickering lights and bulb failure to electric shocks and house fires. This article thoroughly explains the principles, differences, advantages, disadvantages, and application scenarios of these two drive types, ensuring you avoid pitfalls!

In simple terms:

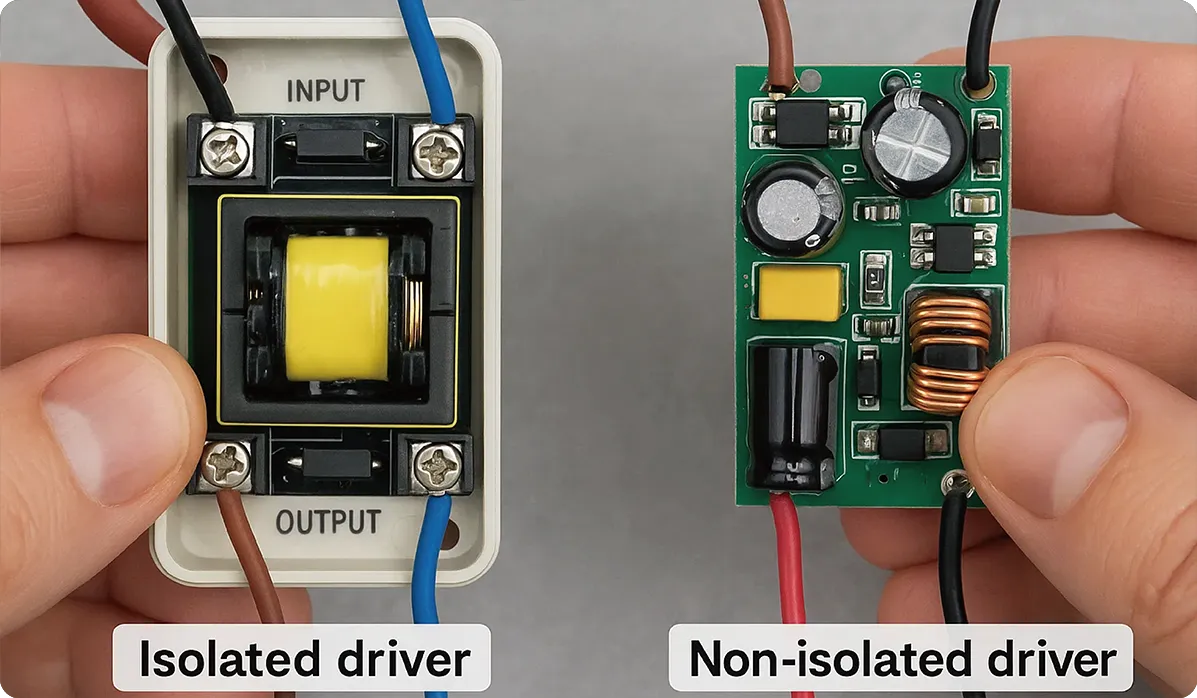

- Isolated drivers ensure the input and output remain ‘unaware’ of each other, using transformers to ‘relay messages’. Even if the input voltage reaches 220V, the output won’t deliver a lethal shock.

- Non-isolated drivers are like sharing a social circle – the input and output are electrically connected. They’re cheaper and more compact, but pose significant risks if something goes wrong.

To illustrate:

Isolated types transmit energy via ‘telephone calls’ – safe,

Non-isolated types deliver electricity ‘face-to-face’ – swift but requires caution.

Category | Core Components | Operating Principle | Safety |

Isolated | High-frequency transformer + optocoupler | Input and output are completely isolated, with energy transfer via magnetic field | High and low voltage can meet SELV requirements |

Non-isolated type | Inductors, capacitors, MOSFETs | Input and output share a common ground, enabling direct buck drive | Low voltage, requiring reinforced insulation |

- Common isolated topologies: Flyback converter – suitable for power ranging from several watts to hundreds of watts;

- Common non-isolated types: Buck converter, linear current-limited – suitable for low-power lighting applications.

Comparison Item | Isolated Driver | Non-Isolated Driver |

Safety | High, suitable for exposed installation environments | Low, requires full system insulation and must not be touchable |

Cost | Medium-high, multiple components and expensive transformers | Low, suitable for high-volume, low-cost products |

Dimensions | Slightly larger, particularly in medium-high power ranges | Compact, suitable for space-constrained applications like light strips and spotlights |

Reliability | Long-term stability, balanced temperature rise distribution | Heat concentrated in MOSFETs and inductors,adequate thermal design required |

EMI Interference | High-frequency switching often requires filtering,optocoupler design increases complexity | Low EMI with proper control, suitable for lightweight lighting |

Common Application Scenarios | Medical lighting, industrial/mining lighting, outdoor lighting, emergency lighting | Domestic LED strips, cabinet lighting, recessed downlights, night lights, etc. |

✅ Suitable for isolated type:

- Medical lighting (bedside lamps, examination lights): Human contact occurs,safety is paramount.

- Outdoor luminaires (street lamps, floodlights): Lightning protection, electric shock prevention, waterproofing.

- Factory emergency/escape lights: Regulations mandate SELV.

- Ceiling recessed downlights (low-clearance spaces): No risk of electric shock even if touched.

✅ Non-isolated types are suitable for:

- Domestic LED strips, cabinet lighting, recessed ceiling luminaires: fully enclosed with no user contact;

- Built-in lighting within low-voltage systems: e.g., luminaires containing isolated power supplies or transformers for prior processing;

- Smart bulbs, battery-powered devices: requiring compact internal space with high demands on volume and efficiency.

Non-isolated power supplies are not unusable, but the following precautions must be observed during operation:

- The luminaire housing must not be conductive, and must never expose any metal surfaces!

- Input voltage must be stable, ideally supplemented with surge protection;

- Equipment must be reliably earthed, with no floating connections permitted;

- The entire luminaire must meet safety certification standards, such as Class II construction or additional insulation protection.

If you are undertaking formal engineering projects or exporting products, the following standards are recommended for inclusion in your design or selection criteria:

Standard Number | Title and Description |

IEC 61347-2-13 | General Safety Standard for LED Drivers / Specific Requirements for Constant Current Drivers |

UL 8750 | General Standard for LED Drivers in the North American Market |

GB 19510.14 | Chinese National Standard, equivalent to IEC 61347 series |

IEC 60598-1 | Overall luminaire safety specification, applicable to whole-luminaire structure earthing and isolation structure assessment |

EN 62493 | Human exposure to EMF testing (European Union market) |

EN 61000-3-2 | EMC electromagnetic interference and harmonic testing specification |

Isolated types offer greater safety, while non-isolated types are more economical. Selecting the right type is like buying a car: focus on the purpose, not the price.

Don’t compromise on safety to save a few quid. When it comes to lighting, it’s not just about brightness – reliability matters most.

Author

Andy Gao

With 15 years in the LED lighting industry, I’ve witnessed its evolution from general fixture production to today’s highly specialized segments. As Co-Founder of Veldstar, my journey mirrors this shift – driving our exclusive focus on pergola and garden lighting solutions. Through dedicated innovation, we develop controllers and systems rivaling leaders like Somfy and Teleco. Here, I share insights and showcase products engineered to elevate outdoor spaces with style, functionality, and advanced control. Learn more via linkendin profile:https://www.linkedin.com/in/pergolalights/

Share This Article:

Send Us your Request