LED strip lighting has become the undeniable foundation of contemporary illumination design. Cherished for its high energy efficiency, flexible installation, and dynamic color options, it transforms lighting from a purely functional necessity into a sophisticated design element.

Yet, trying to find a definitive answer to “who invented LED strip lights?” or “when were LED strip lights invented?” is surprisingly difficult. This is because the strip light is not a singular invention but a product born from the convergence of three major technological breakthroughs.

This comprehensive guide will trace the history of this flexible revolution, provide precise answers to your most pressing historical questions, and introduce crucial technical terms (like low voltage LED strip lights vs high voltage) and tips to help you select the best product.

The story of the LED strip begins with its core component: the Light Emitting Diode (LED) itself.

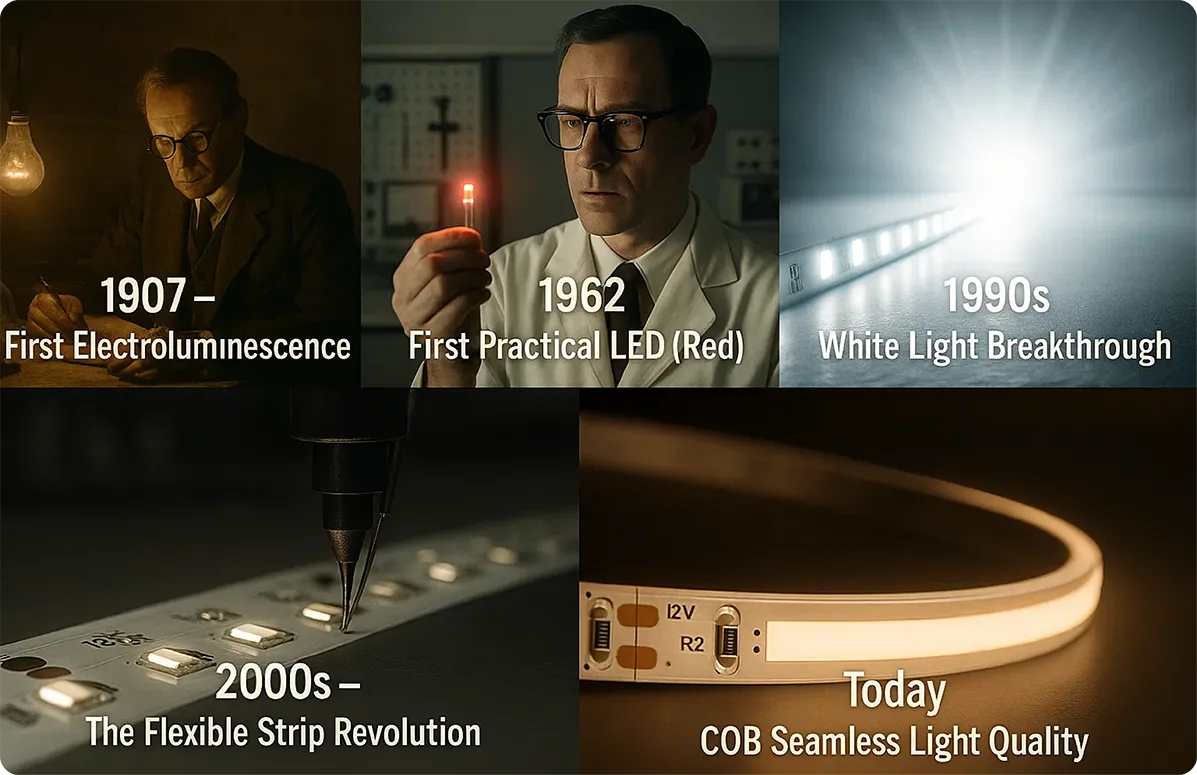

The First Spark: Electroluminescence in 1907

In 1907, British scientist H.J. Round observed the phenomenon of electroluminescence—the emission of light from a material when an electric current is passed through it—using a silicon carbide crystal. This discovery laid the theoretical foundation for all subsequent solid-state lighting.

The Practical Breakthrough: The First LED in 1962

The world had to wait until 1962 for the first truly practical visible-spectrum LED. Nick Holonyak Jr., working at General Electric, is credited with inventing this device. These early LEDs emitted a dim red light and were primarily used as mere indicator lights in electronic devices. Holonyak is widely hailed as the “Father of the LED.”

The leap from a tiny red indicator light to a versatile, white light strip was dependent on two crucial developments: solving the white light challenge and mastering flexible manufacturing.

Solving the White Light Problem

White light—essential for general lighting (General Lighting)—was the key hurdle. The breakthrough came with the development of the blue LED in the 1990s. When combined with phosphors or other colors, the blue LED finally allowed for the creation of usable, bright white light.

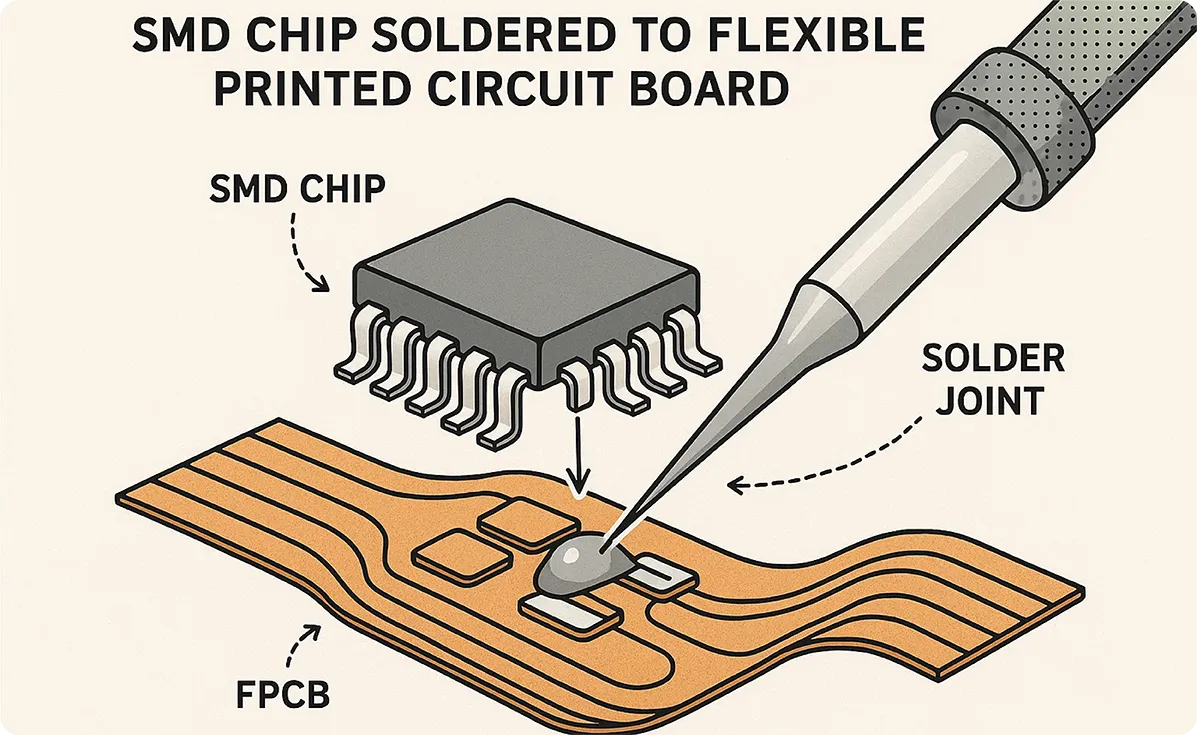

Core Technological Integration: FPCB and SMD

The physical transformation of the LED into a “strip” required two manufacturing innovations:

- Surface-Mount Device (SMD): This technology allowed tiny LED chips to be directly and densely soldered onto the surface of a circuit board.

- Flexible Printed Circuit Board (FPCB): The FPCB is the bendable, low-profile substrate that gave the strip its namesake flexibility and cut-to-length capability.

Pinpointing the Birth of the LED Strip Light

The question of “When were LED strip lights invented?” (and its variants like when were led lights strips invented) has no single calendar date. The consensus is that LED strip lighting emerged as a marketable, commercial product in the early 2000s (approximately 2000-2003). It was the convergence of mature SMD technology, available white LEDs, and affordable FPCB manufacturing that made the product a reality.

The First Use Case: Replacing Neon and Decorative Lighting

Early LED strips were predominantly used as a versatile replacement for traditional neon and fluorescent strip lighting. Their low-voltage operation, greater energy efficiency, and superior flexibility made them ideal for decorative lighting, signage, and accent lighting where traditional bulkier sources couldn’t fit. This answers the query “what was led strip lighting first used for.”

Mid-2000s Popularity and Initial Challenges

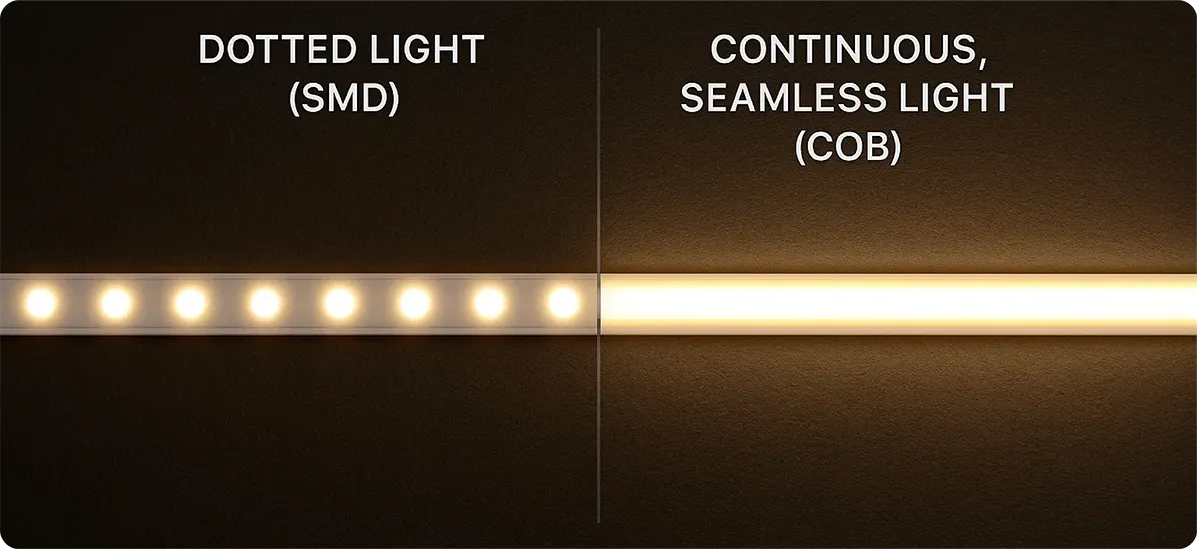

By the mid-2000s ($sim 2005$), LED strip lights began to gain widespread popularity, driven by increasing energy costs. However, early versions struggled with visible light dots (“spotting”) and heat dissipation, which often led to premature degradation. This laid the groundwork for the next generation of technological advancements.

Miniaturization and High-Density Packaging

Advancements in SMD technology led to smaller chips (e.g., the move from 5050 to 2835), allowing for higher LED density and greater light output per meter.

A Leap in Lighting Quality: COB, CRI, and Beam Angle

The pursuit of better light quality has introduced new technologies essential for professional-grade lighting.

COB (Chip-on-Board) Strip Lights Emerge

COB technology involves directly mounting the LED chips onto the circuit board and covering them with a continuous layer of phosphor. This innovation fundamentally solves the “spotting” problem, offering a seamless, dot-free line of light, and covering the user intent behind searching for types of led strip lights.

The Importance of Color Rendering Index (CRI)

Professional applications demand high-quality light. High CRI (typically 90+) ensures that colors under the LED light look natural and true-to-life.

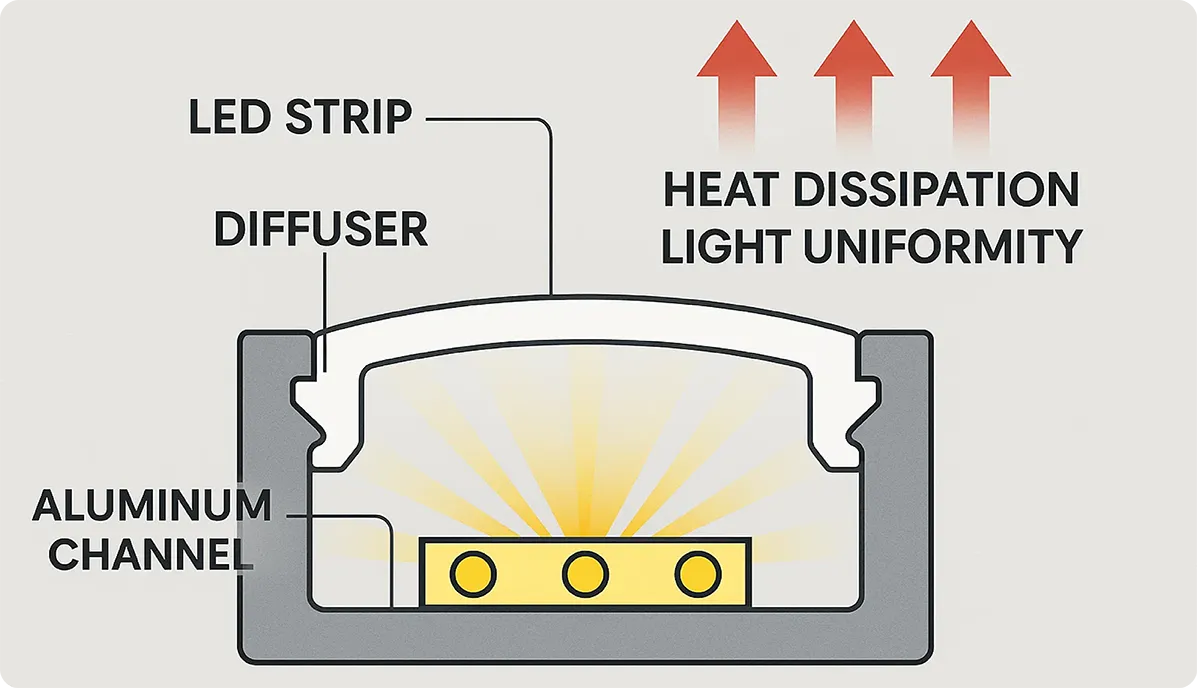

Optimizing the Beam Angle (led strip light beam angle)

While many think of LED strips as omnidirectional, the way light is distributed is critical. Proper installation often involves aluminum profiles and diffusers to manage the beam angle, ensuring the light is evenly spread and glare is minimized.

For long-term use, choosing the right specifications is paramount

Understanding Lifespan: L70 Standard

The lifespan of an LED strip (answering how long do led strip lights last) is typically measured by the L70 standard—the time it takes for the light output to degrade to 70% of its initial brightness. Most high-quality strips rate between 25,000 to 50,000 hours.

The Crucial Role of Heat Management

The primary factor shortening LED lifespan is heat. Effective heat dissipation via aluminum channels is not just for aesthetics; it is vital for maintaining the strip’s longevity.

Low Voltage vs. High Voltage Strips (low voltage led strip lights vs high voltage)

Feature | Low Voltage (12V/24V) | High Voltage (110V/220V) |

Safety | Very Safe (Ideal for homes/DIY) | Requires Professional Installation |

Max Run Length | Limited (Requires repeaters for long runs) | Very Long (Up to 50m) |

Cut Points | Very frequent (Every few cm) | Infrequent (Every 0.5 to 1 meter) |

Wiring Basics: Connecting to a Switch (how to wire led strip lights to switch)

LED strips require a DC power supply (driver). To wire them to a standard AC wall switch, you simply connect the AC input of the LED driver to the switch’s output. This allows the switch to control the entire system, turning the DC light on or off safely.

The Architect’s Secret: Hidden Light in Interior Design

LED strips excel in creating atmosphere through cove lighting, under-cabinet lighting, and backlighting for mirrors and shelving. Their low profile makes them the ideal solution for sophisticated, indirect illumination.

Commercial & Automotive Use Cases

- Commercial: Used extensively in retail to spotlight products and in hospitality to craft unique ambient experiences.

- Automotive: LED strips in cars (addressing led strips in cars) are used for highly customizable interior mood lighting and exterior accent lighting, thanks to their 12V compatibility.

The future of LED strip lighting is centered on intelligence and integration. Smart control systems and IoT integration will continue to make lighting more personalized and automated. Emerging technologies like Micro-LED promise even higher energy efficiency and superior color purity for the next generation of flexible lighting solutions.

Q1: Why do LED strip lights burn out prematurely? (why do led strip lights burn out)

A: The main cause is excessive heat. Without proper heat dissipation (like using an aluminum channel), the LED chips operate at high temperatures, which accelerates the degradation of the phosphor and internal components, leading to a much shorter lifespan than advertised.

Q2: Can LED strip lights be used outside? (can led strip lights be used outside)

A: Yes, but they must have an appropriate Ingress Protection (IP) rating. For outdoor use, look for strips rated IP65 (splash-proof) or IP67/IP68 (submersible/weatherproof) to protect the components from moisture and dust.

Q3: Is it safe to cut LED strip lights? (is it safe to cut led strip lights)

A: Yes, it is perfectly safe to cut low-voltage LED strips, provided you cut exactly on the marked copper cutting line. Cutting elsewhere will damage the circuit and may ruin the segment. Always ensure the strip is unplugged from the power source before cutting.

Q4: How do I choose the right LED strip power supply? (how to choose led strip power supply)

- Calculate Total Wattage: Multiply the strip’s wattage per meter by the total length (in meters) you plan to use.

- Add 20% Buffer: Always oversize the power supply by at least 20% to prevent overloading and ensure longevity. For example, for 50W of strips, choose a 60W or 75W power supply.

Q5: Are LED light strips flexible? (are led light strips flexible)

A: Yes, the inherent flexibility comes from the FPCB (Flexible Printed Circuit Board) backing. However, you must respect the minimum bending radius; bending them too sharply can damage the internal circuits.

Q6: What is the main difference between SMD and COB strip lights?

A: SMD strips have individual LED dots that are visible and require a diffuser to eliminate spotting. COB strips, due to their chip-on-board design, provide a continuous, dot-free line of light, offering superior uniformity and better thermal performance.

The LED strip light is a remarkable product whose evolution spans more than a century of scientific effort, from H.J. Round’s early observations to today’s smart, versatile systems. Its success lies in its ability to adapt and integrate, offering solutions that no other lighting technology can match.

Author

Andy Gao

With 15 years in the LED lighting industry, I’ve witnessed its evolution from general fixture production to today’s highly specialized segments. As Co-Founder of Veldstar, my journey mirrors this shift – driving our exclusive focus on pergola and garden lighting solutions. Through dedicated innovation, we develop controllers and systems rivaling leaders like Somfy and Teleco. Here, I share insights and showcase products engineered to elevate outdoor spaces with style, functionality, and advanced control. Learn more via linkendin profile:https://www.linkedin.com/in/pergolalights/

Share This Article:

Send Us your Request